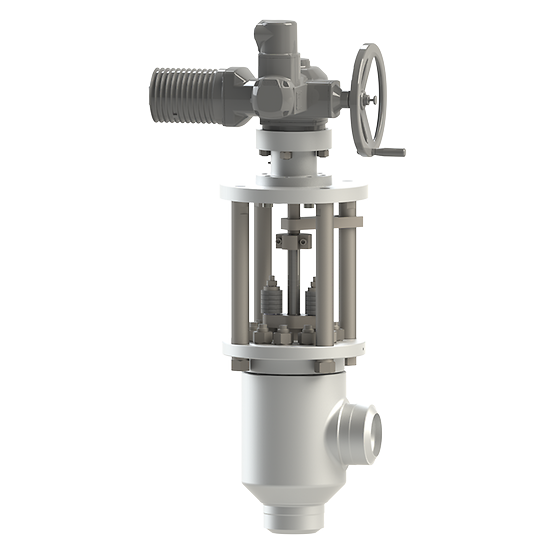

Sempell Model 142 High Pressure Water Control Valve

Any questions?

Linda Grönqvist

Solution Seller

Phone. +46 40-33 02 32

Niklas Pettersson

Account Manager

Phone. +46 54-57 92 09

Anders Praem

Inside Sales Engineer

Phone. +45 2137 7759

Frank Kirk Hansen

Area Account Manager West

Phone. +45 4053 6511

Slawka Pedersen

Inside Sales Manager

Phone. +45 2137 7702

Henna Ketoja

Inside Sales Engineer

Mob. +358 400 612 124

Risto Wallin

Country Manager Askalon Finland, Key Account Manager Nuclear

Phone. +358 207 416 209

Mob. +358 400 448 248

Specially designed low-maintenance control valves for a wide range of applications in water circulation.

Sempell™ series 142 designer angular water control valves for the following applications:

• Water injection at HP/IP Bypass.

• Feedwater Start-up Control valve.

• Minimum Flow valve at Feedwater pumps.

• Blow-down valve at drum boilers.

The narrowly scaled Cv values-series and a large control ratio allow an exact adjustment for the respective task. The trims can be easily changed. A huge combination of material choices and multi pressure reduction stages.